Chitosan is a naturally occurring biopolymer derived from chitin, a substance found in the exoskeletons of crustaceans such as crabs, shrimps, and lobsters, as well as in the cell walls of fungi. Its unique properties and biocompatibility make it a versatile material for various applications across industries. This article explores the structure, properties, production, and applications of chitosan.

Structure and Properties

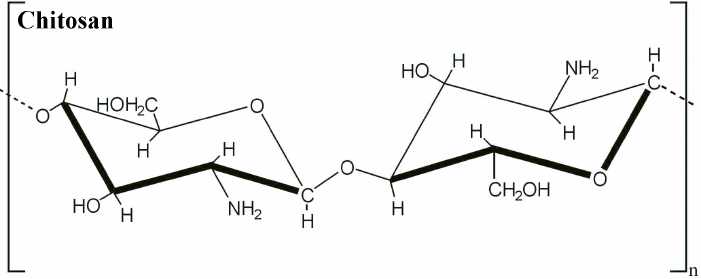

Chitosan is a linear polysaccharide composed of D-glucosamine and N-acetyl-D-glucosamine units linked by β-(1→4) glycosidic bonds. The degree of deacetylation (DD), which measures the proportion of glucosamine units, determines its solubility and functional properties. Chitosan is soluble in acidic solutions, forming a cationic polymer that interacts with negatively charged molecules, a key feature responsible for its various applications.

Key properties of chitosan include:

- Biodegradability: Chitosan can break down into harmless byproducts in the environment.

- Biocompatibility: It is non-toxic and well-tolerated in biological systems.

- Antimicrobial Activity: Chitosan exhibits antimicrobial properties against bacteria, fungi, and viruses.

- Film-Forming Ability: It can form transparent and flexible films.

- Chelating Capacity: Chitosan binds to heavy metals and other contaminants, aiding in water purification.

Chitosan chemical structure

Production

The production of chitosan involves two main steps:

- Extraction of Chitin: Chitin is extracted from raw materials such as shrimp or crab shells through demineralization and deproteinization processes.

- Deacetylation of Chitin: Chitin is treated with alkali, typically sodium hydroxide, to remove acetyl groups, converting it into chitosan. The degree of deacetylation can be adjusted to achieve desired properties for specific applications.

Applications

1. Biomedical Field

Chitosan’s biocompatibility and biodegradability make it an attractive material for biomedical applications:

- Drug Delivery: Chitosan-based nanoparticles and hydrogels are used for targeted drug delivery systems.

- Wound Healing: Its antimicrobial and film-forming properties aid in creating wound dressings that promote healing.

- Tissue Engineering: Chitosan scaffolds support cell growth and tissue regeneration.

- Dental Applications: It is used in toothpaste and mouthwashes for its antibacterial properties.

2. Food Industry

In the food industry, chitosan serves various purposes:

- Preservative: Its antimicrobial activity helps extend the shelf life of perishable foods.

- Edible Coatings: Chitosan-based coatings are used for fruits, vegetables, and meat products.

- Dietary Supplement: It is marketed as a fat-blocking agent in weight management products.

3. Agriculture

Chitosan contributes to sustainable agriculture:

- Plant Growth Enhancer: It acts as a biostimulant, improving plant resistance to diseases and pests.

- Seed Coating: Chitosan-coated seeds show better germination rates and growth performance.

4. Water Treatment

Chitosan’s ability to chelate heavy metals and adsorb pollutants makes it valuable in water purification processes. It removes contaminants such as lead, mercury, and organic dyes from industrial wastewater.

5. Cosmetics

In cosmetics, chitosan is used for its moisturizing, film-forming, and antimicrobial properties. It is a common ingredient in skin creams, shampoos, and anti-aging products.

Environmental and Economic Considerations

The production of chitosan from crustacean waste offers an eco-friendly solution to managing seafood industry byproducts. However, challenges such as resource availability, variability in raw materials, and production costs remain. Advances in fungal-based chitosan production are promising alternatives that could overcome these limitations.