Soy Lecithin Brief

Commercial soybean lecithin Liquid is a complex mixture containing ca.65-75% phospholipids together with triglycerides and smaller amounts of other substances. Orison Chemicals Limited is committed to producing high-quality soy lecithin from soybean oil. Its products include Crude soy Lecithin oil and refined Soy Lecithin Liquid, transparent phospholipid, Low-Viscosity Soy Lecithin, Deoiled soy lecithin, Feed Grade soy lecithin powder. The products are certified by FSSC, HACCP, Kosher, and Halal and are widely used in food, feed, industry, coatings, and other industries.

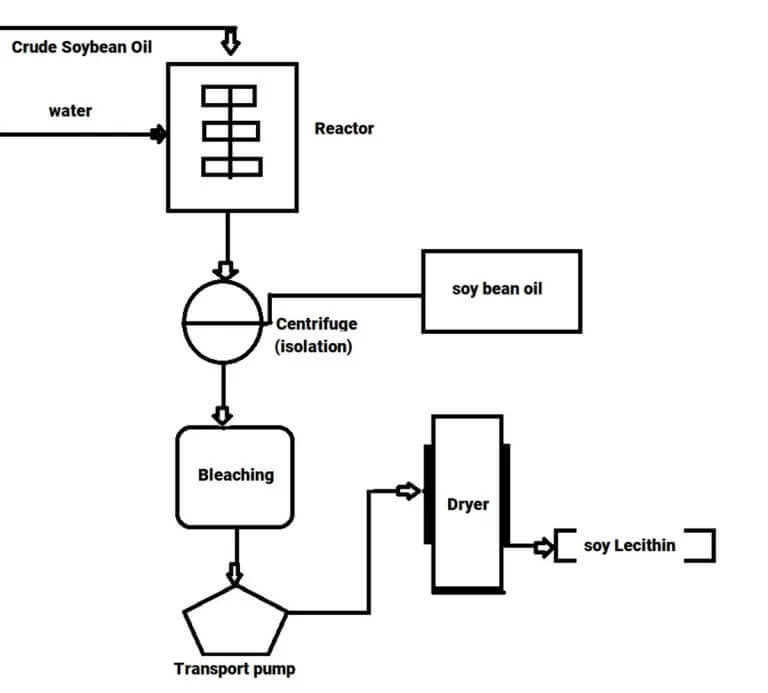

Crude Soy Lecithin Production Process:

1. Crude soybean oil degumming process (Intermittent degumming or Continuous degumming)

In the batch method, the crude oil is first added to the reactor, the temperature is raised to 70~82℃, and then 2%~3% of water and some additives (such as acetic anhydride) are added. Under stirring, the oil and water react with each other. The hydration reaction is fully carried out in the kettle for 30-60 minutes. The reacted materials are sent to the degumming centrifuge.

Continuous degumming is carried out in pipelines, and raw crude soybean oil is basically continuously produced through processes such as oil hydration, phospholipid isolation, and finished product storage. The feeding method is to continuously send a fixed amount of water or steam and oil into the pipeline at the same time so that the oil and water are fully mixed in the pipeline.

2. Soy Lecithin Isolation with soybean oil

After the dehydrated crude soybean oil is degummed, the oil and phospholipids are isolated by the centrifuge. it must be dehydrated with thickening equipment (such as a thin film evaporator). The dehydration method can also adopt intermittent dehydration and continuous dehydration. Intermittent dehydration is vacuum evaporation at 65~70℃. For continuous dehydration, a thin film evaporator is used to evaporate for 2 minutes at a pressure of 2.0 ~ 2.7 kPa and 115°C. The moisture content of the final product should be less than 0.5%. The dehydrated jelly must be quickly cooled to below 50°C to prevent the color from becoming darker. Since colloidal phospholipids are generally stored for more than a few hours, in order to prevent the spoilage of bacteria, diluted hydrogen peroxide is often added to the wet gel to have a bacteriostatic effect.

3. De-color processing

Decolorization uses 3% hydrogen peroxide to decolorize. When the dosage is 1.5%, the degree of decolorization can be reduced by 14. Using 1.5% benzoyl peroxide to decolorize twice, the color can be reduced by 12. Each peroxide acts on a different color system. For example, hydrogen peroxide reduces brown pigments and is very effective in treating yellow. Benzoyl peroxide can reduce red pigment and is more effective in processing red. The two decolorizing agents mentioned above can be used together to obtain phospholipids with relatively light colors. The most suitable temperature for decolorization is 70°C. In addition, it is also used for the decolorization of substances such as sodium hypochlorite and activated carbon.

4. Drying

Drying Batch drying of phospholipids is the most common method, and vacuum drying is the most reasonable method. Since phospholipids must prevent foam during vacuum drying, vacuum drying is difficult, the degree of vacuum must be carefully controlled and a longer drying time (3 to 4 hours) must be used. In addition, film drying is also a very successful method. It can prevent the phospholipid from blackening through the cooling circuit and has a good effect on removing the acetic acid residue added in the degumming process towel.

5. Soy Lecithin Refining

Refining removes soybean oil fatty acid and other impurities in crude phospholipids, so as to obtain a higher content of phospholipids. The crude soy lecithin and acetone are prepared in a ratio of 1:(3~5) (mass ratio), and stirring is continued undercooling, the oil and fatty acids are dissolved in acetone, and the phospholipids are precipitated and separated.